On December 12th, Guangqi Aion’s Yinpai Battery Intelligent Ecological Factory officially completed and started production, and at the same time released a new breakthrough in the P58 microcrystalline super energy battery. It is high safety, high performance, and long life, with the battery core not smoking or catching fire when punctured. Ma Shu, Deputy Secretary General of the Guangzhou Municipal Government, Chen Dejun, Director of the Guangzhou State-owned Assets Supervision and Administration Commission, Zeng Qinghong, Chairman of Guangqi Group, Feng Xingya, General Manager, Gu Huinan, General Manager of Guangqi Aion, and Xu Junhai, head of Yinpai Battery Technology Co., Ltd., attended the completion ceremony.

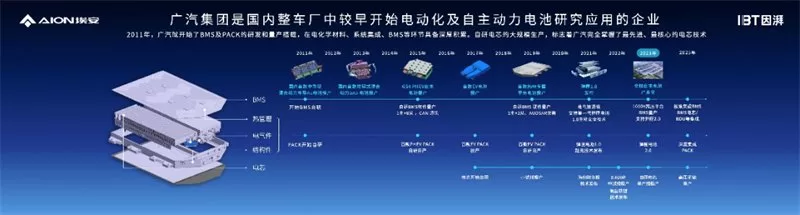

The self-developed and self-produced full-stack battery has been accumulating strength and making breakthroughs. The P58 microcrystalline super energy cell is far ahead! In recent years, domestic new energy vehicle companies have emerged like mushrooms after the rain, and policy promotion is undoubtedly an important reason. Since 2010, new energy vehicles have been listed as one of China’s seven strategic emerging industries. However, at that time, the industry still held a wait-and-see attitude towards the development of new energy vehicles, and few car companies truly ventured into the field of power batteries. As one of the domestic vehicle manufacturers that started early in the development and application of electric power and independent power batteries, GAC Group began the research and development of battery systems and BMS in 2011. The first independently designed PHEV battery pack was installed in the GS4 PHEV in 2015, and GAC Aion’s first independently developed EV battery pack went into production in 2017. In the same year, the independent research and development of power battery cells and the construction of a cell test line were initiated. Starting in 2021, a series of advanced battery technologies such as magazine battery system safety technology, sponge silicon negative electrode battery, and ultra-fast battery were successively released. In 2022, the cell pilot line was completed and put into use. Years of technological accumulation have laid a solid foundation for the large-scale production of independent power batteries today.

After careful calculation, GAC Aion has accumulated reserves in the field of battery R&D for as long as 12 years. With the completion of the Paili battery intelligent ecological factory, GAC Aion has officially mastered the ability to independently develop and produce battery cells. As the latest product of the magazine battery 2.0 series, the P58 microcrystalline super energy cell overcomes various material and technical difficulties, and has the characteristics of ultra-high safety, high energy density, long life, and excellent fast charging performance.

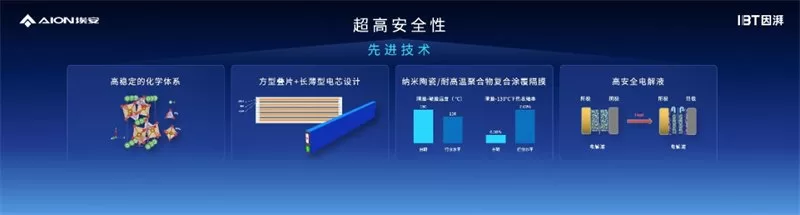

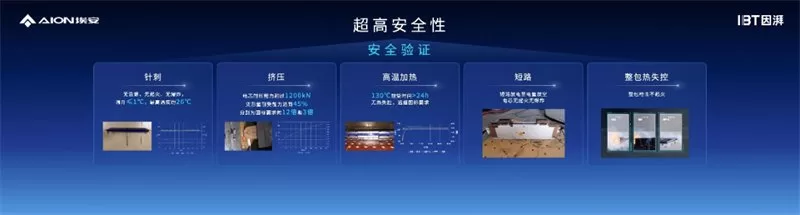

In terms of battery safety, the P58 microcrystalline super power battery is based on a highly stable lithium iron phosphate positive electrode chemical system, nano-ceramic/high-temperature resistant polymer composite coated separator, and high safety electrolyte technology, truly achieving no smoke, no fire, and a temperature rise of less than 1℃ during the battery puncture process, with almost no change. It can also withstand high-intensity compression without failure, with a pressure resistance capability exceeding 1200kN and a deformation tolerance capability of 45%, exceeding the national standard requirements by 12 times and 3 times respectively. Coupled with the magazine battery 2.0 technology, it can achieve no fire when the entire battery is shot, reshaping the new standard for battery safety.

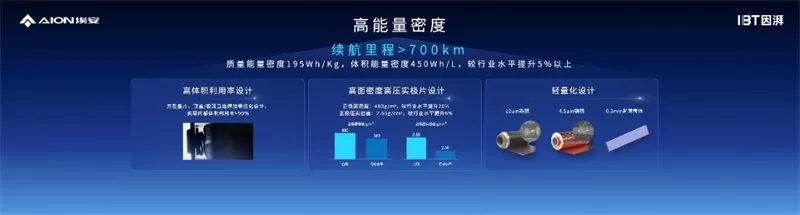

To achieve high energy density, the P58 microcrystalline ultra-energy cell is optimized through square stacking, direct welding of top cover/pole ears, achieving an internal volume utilization rate of over 90%, and ultimately achieving a vehicle range of over 700km, even higher than many ternary lithium battery densities. It also has 3C fast charging capability, achieving a 10-minute charge for a 250km range, further addressing user range anxiety.

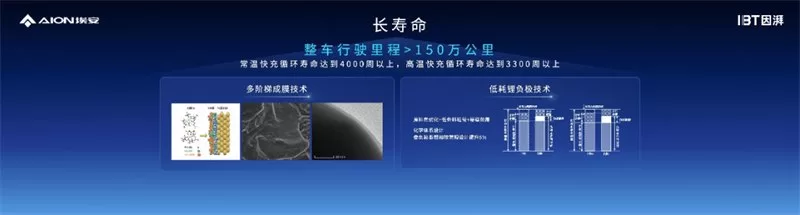

The key improvement is the significantly extended lifespan, thanks to the application of multi-step film formation and low-consumption lithium anode technologies. The normal temperature fast charge cycle life of P58 microcrystalline super energy battery reaches over 4000 weeks, and the high temperature fast charge cycle life reaches over 3300 weeks. The theoretical driving range of the whole vehicle can exceed 1.5 million kilometers, an increase of over 25% compared to the industry mainstream level.

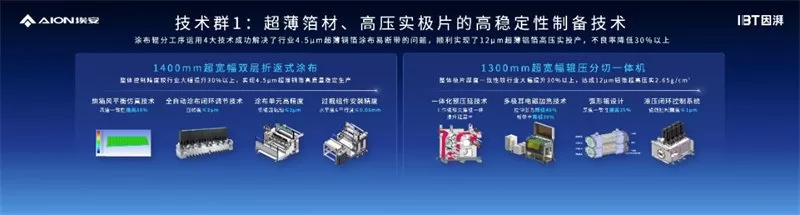

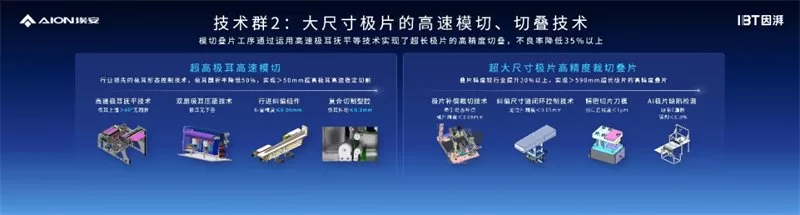

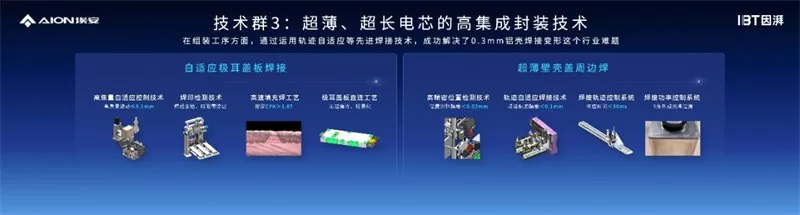

Currently, all products under GAC Aian use magazine batteries, with more than 650,000 vehicles produced and no cases of spontaneous combustion. With the mass production of the new generation P58 microcrystalline super energy battery, the future will empower the Aian and Haobo brands, undoubtedly greatly increasing their competitiveness and further boosting sales. Five leading benchmark factories worldwide redefine the new standard of lithium battery intelligent manufacturing in the TWh era. Advanced battery cells not only need to be developed, but also need to be manufactured efficiently and with high quality. The precision control of quality in the manufacturing process, such as rolling, stacking, and welding, directly affects the safety and energy density of the battery. Therefore, when the intelligent ecological factory of Yinpu Battery was proposed, the development of advanced process technology was given the same importance as the development of advanced products. In order to achieve the large-scale high-quality production of the P58 microcrystalline super energy battery, Yinpu Battery’s intelligent ecological factory has developed three major process manufacturing groups, including ultra-thin foil material, ultra-high stability, and ultra-high pressure solid pole intelligent manufacturing technology; high-speed cutting and stacking technology for large-size pole pieces; and ultra-thin, ultra-long battery cell highly integrated packaging technology, with an overall control precision increase of more than 30% compared to the industry.

Based on three major production techniques, the intelligent ecological factory of YINDA Battery also utilizes advanced technologies such as big data and AI to establish five benchmarks for battery factories and redefine the new standard for lithium battery intelligent manufacturing in the TWh era.

As the world’s first benchmark factory for extreme craftsmanship and safety, Inpower Battery’s intelligent ecological factory is fundamentally focused on preventing thermal runaway of battery cells, establishing process safety control standards to ensure process consistency, achieving “zero” foreign objects and burrs in extreme slices, strengthening extreme limit verification, and enhancing product safety to the utmost. To meet the quality requirements of aviation, Inpower Battery’s intelligent ecological factory has raised the target for defective products to 10-9. Through ultra-high-level process design and the creation of super-advanced intelligent production lines, it has achieved ultra-high-precision inspection, making it the world’s first benchmark factory for aviation-grade quality. Inpower Battery’s intelligent ecological factory is also the world’s first ultra-efficient flexible benchmark factory, with a production cycle of seconds for battery cells and the highest single-line capacity of 6GWh in the world. It can achieve mixed-line production of the entire product range, with battery cell type changes in hours, seamless PACK type changes, and a reduction of over 90% in capacity switching losses, achieving extreme efficiency and deep integration of ultra-high flexibility. In terms of digital applications, Inpower Battery’s intelligent ecological factory adopts a cloud-native technology architecture, with specific focuses on digital twinning, data-driven decision-making, and intelligent data monitoring. It has set up over 15,000 data monitoring points to connect and cover research, production, supply, and sales data in all business areas, effectively improving operational efficiency and research and development iteration speed, while also reducing production waste and overall factory energy consumption, making it the world’s first benchmark factory for digital native intelligent manufacturing. In addition, Inpower Battery’s intelligent ecological factory has also created a leading low-carbon environmental benchmark factory through three major initiatives: green electricity, energy conservation, and waste recycling, reducing annual carbon dioxide emissions by over 25,000 tons, equivalent to planting over 2.52 million trees per year.

In summary, the BYD battery intelligent ecological factory can maximize the value of personnel, achieve zero-defect intelligent manufacturing, greatly improve production efficiency, and significantly reduce inventory levels, achieving the ultimate benefits and cost optimization. Outstanding craftsmanship and top-notch manufacturing standards are required to perfectly reproduce industry-leading battery technology. It is reported that the initial phase of the BYD battery intelligent ecological factory can achieve a capacity of 6GWh, and the later phase will complete the introduction of a 36GWh production line, while meeting the demand for 600,000 units. Various batteries such as sodium-ion batteries and all-solid-state batteries will also be mass-produced on this production line. GAC Aian’s energy ecological closed loop welcomes the final piece of the puzzle. The official production of the BYD battery intelligent ecological factory is of great significance to GAC Aian. As the electrification era continues to evolve, competition in the automotive industry is shifting from a simple “product” competition to a “product + ecology” competition. For new energy vehicles, batteries are the key factor in power supply and production manufacturing costs, and are also a core and decisive factor in the future competition of the new energy vehicle industry.

Guangqi Group has always adhered to the measures of “selecting the best from external sources, joint venture cooperation, and independent development”. As one of the very few companies in the world with the capability of independently researching and producing battery cores, GAC Aian can cover all vehicle models such as A/B/C-class sedans and SUVs with just one battery core, providing more extreme performance and better cost-effectiveness. This exclusive development capability is also essential for the development of high-end pure electric vehicles and is crucial for GAC Aian to make an impact on the high-end market and enhance the overall strength of its high-end luxury brand, Haobo.

On the other hand, with the completion of the Pinnacle Battery Intelligent Ecological Factory, it marks that GAC Aion has fully connected the energy ecological industry chain layout including upstream raw materials, R&D, manufacturing, battery recycling, and cascaded utilization, completing the core puzzle of the energy ecology, officially becoming an energy company, and also one of the very few global host factories to achieve full-stack self-research and production of batteries. In the future, GAC Aion will take the Pinnacle Battery Intelligent Ecological Factory as the core, build an energy ecology around “electricity + battery” including light storage and energy supply network, energy network autonomous driving, cascaded utilization of batteries, battery bank and other businesses, and further enhance the new space of efficiency.

Certainly, building the intelligent ecological factory of GAC Aian Battery is just a microcosm of GAC Aian’s high-quality development in recent years. In the first 11 months of this year, GAC Aian’s cumulative sales reached 434,056 units, and the total production and sales since the start of production has exceeded 950,000 units, just a step away from the one million mark. Previously, car companies that first reached the one million mark took 5 years for Wuling, 7 years for Lynk & Co, 12 years for Tesla, 13 years for BYD, and 35 years for Toyota… In other words, GAC Aian, which has been in production for less than 5 years, may become the fastest car brand in the world to break through the one million mark in production and sales! On the basis of solidifying sales, GAC Aian’s dual-brand year has also produced outstanding results. As the high-end luxury brand under GAC Aian, Haobo has launched three masterpieces: the pure electric luxury supercar Haobo SSR with a 1.9-second 0-100 acceleration performance, the Haobo GT, representing the 20 millionth new energy vehicle in China, and the Haobo HT, the preferred choice for elite families. Facing the next stage of competition, GAC Aian has made full preparations. In addition to the completion and production of the GAC Aian Battery Intelligent Ecological Factory, the Rui Pai Electric Drive Factory, with a total investment of 2.16 billion yuan and controlled by GAC Aian, is also nearing completion, and the Quark Electric Drive, which has halved in size and doubled in power, will soon be self-produced. Therefore, GAC Aian will integrate the three electric systems of the whole vehicle, no longer separating them, and through a leading, stable, and independently controllable industrial chain layout, it is accelerating towards the next one million sprint.