According to data, the current market share of domestic new energy vehicles is close to 40%, and the number of users who consider new energy vehicles as their first purchase plan is constantly increasing. In the past, when you purchased traditional fuel vehicles, you would definitely consider the hardware quality of the three major components of the car. However, in the era of new energy, the new three major components of the car have become the motor, the electronic control, and the battery. Among them, the battery, as the main energy storage for new energy pure electric vehicles, its performance has a very important impact on the vehicle’s endurance and overall safety. In recent years, various brands have been continuously advancing the development of power battery technology.

On December 14th, at the “Ji Ke Energy Day 2023” held in Quzhou, Ji Ke Automotive released its latest self-developed battery technology – the “Golden Brick” battery. The battery uses the lithium iron phosphate battery route and will first be installed on its new model, Ji Ke 007. At the same time, the event also announced the future development and planning of Ji Ke’s ultra-charging stations, and the first 20kW home charging pile officially went on sale tonight.

The Jike brand has been focusing on core technology in the field of new energy vehicles since its establishment. From the first Jike model with a 100-degree battery, to the global first Jike 001 Long-range version with a 140-degree Kirin battery, to the ultimate performance of the Jike 001 FE, the Jike brand has repeatedly proven its own technological strength to the industry and consumers. At the Jike Energy Day 2023 conference, the Jike brand once again refreshed everyone’s understanding of batteries and technological bottlenecks, and released the “Brick Battery,” which is the world’s fastest-charging lithium iron phosphate battery in mass production. It is produced at the largest global integrated base for smart manufacturing of three-electric and energy storage systems – the Quzhou Jidong Factory, with multiple self-developed innovative production technologies.

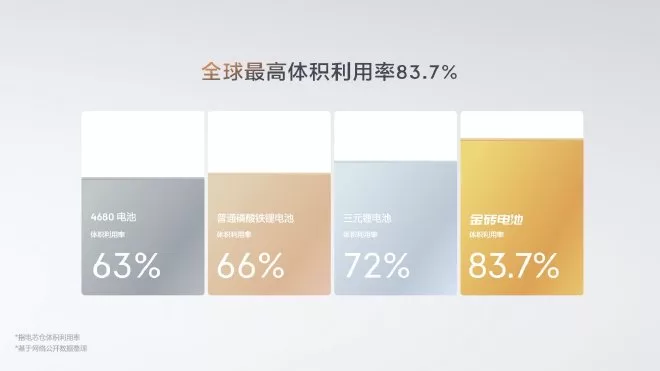

High volume utilization allows for larger battery capacity Increasing the range of pure electric vehicles, the most direct way is to increase the volume of the battery. Although the commonly used lithium iron phosphate battery has advantages such as low cost and good high temperature resistance, compared to ternary lithium batteries, the “room for improvement” inside the battery is not high. In other words, if you want to cram more battery cells into the battery pack, the volume will inevitably be very large. This is also why lithium iron phosphate battery packs are usually used in SUVs and MPVs, which have larger body sizes.

And this release of the brick battery, using extreme materials and innovative high-density integrated design, allows the battery to live in the large flat. The bottom of the battery uses an integrated liquid-cooled tray, increasing the volume utilization rate by 8.5%, and also adopts a “compact sandwich structure” of the battery core, upper cover, and bottom plate, releasing longitudinal space of the battery compartment and increasing utilization by 7.6%. The ultra-thin thermal resistance material of aviation grade is used between the battery cores, increasing the volume utilization rate by 6% while ensuring safety. Compared with the industry-known 4680 battery with a volume utilization rate of 63% and the current ternary lithium battery with a volume utilization rate of 72%, the brick battery has the highest volume utilization rate of 83.7%.

At the same time, the gold brick battery also adopts a highly efficient integrated design, which greatly optimizes the internal structure of the battery, reduces the number of core components by 35%, reduces the total length of the sampling harness by 157m, reduces the total cost of external components by 23%, and greatly reduces the structural components, enabling the battery quality energy density to increase by 10%+.

Extreme charging for 15 minutes extends the range by over 500 kilometers The golden battery not only achieves a leading level in terms of energy density, but also benefits from the vast architecture of the global 800V platform. With the 800V extreme charging V2/V3 charging stations, the highest charging power can reach 500kW, achieving a maximum charging rate of 4.5C. Charging for 15 minutes extends the range by 500 kilometers, to a certain extent, solving the users’ anxiety about range and recharging.

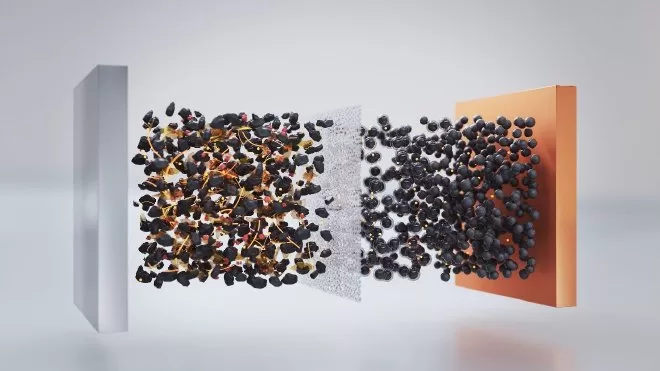

At the same time, the performance of the gold brick battery is also excellent. It adopts a stacked multi-pole ear structure design in the cell structure, with more uniform heat distribution and more efficient temperature control under ultra-fast charging conditions. It adopts a double-riveted pole flow design, which increases the overcurrent capacity by 100% compared to a single pole. The 3-second pulse discharge rate can reach 16C, providing reliable and strong burst power for high-performance models, easily entering the 3-second level of zero to one hundred acceleration. The gold brick battery also has excellent low-temperature performance, and the “lithium-ion full-range acceleration technology” can ensure stable charging speed even at -10 degrees Celsius.

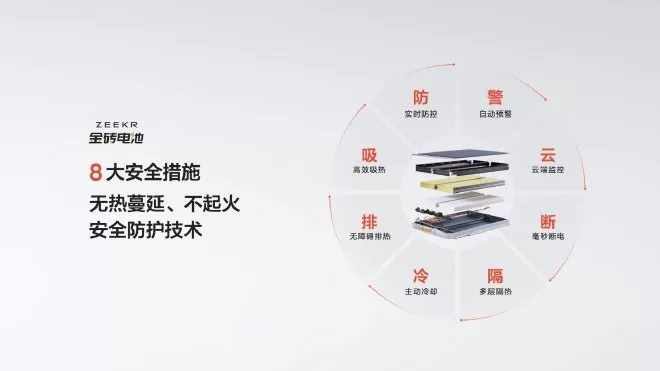

Extreme safety testing ensures battery safety Battery safety has been a concern since the early days of new energy vehicles. This time, the Jinzhuan battery has adopted 8 major thermal safety protection technologies to actively safeguard the safety of the battery.

Next, JiKe surpasses national standards in battery design and safety testing. For example, in the external fire test, it burns directly in a fire of over 700°C for 240 seconds, far exceeding the national standard of 130 seconds. After the test, the battery pack was left undisturbed for 2 hours and no fire, explosion, or thermal runaway occurred. The cell voltage and pack insulation remained normal. To verify the safety of the JiKe battery, the R&D team conducted the industry’s first “compression + needle puncture” combined safety test on the battery cells. First, a cell with 100% SOC was compressed with 1.5 times the national standard pressure, resulting in deformation of over 30%, exceeding the national standard by more than 2 times. After 1 hour, a 5mm steel needle was used for a puncture test, causing a short circuit inside the cell. Throughout the test, the cell did not catch fire or explode, and the highest surface temperature reached was only 33.0°C. JiKe named this test “overpressure needle puncture.” In addition, the JiKe battery also underwent 6 extreme condition tests, including high-concentration saltwater immersion, freezing, dragging, rolling, and high-altitude drops, to fully verify the safety and reliability of the battery.

Accelerate the construction of supercharging network and promote the convenience of 1515 electric. Jike this time not only released the gold brick battery, but also announced the future supercharging network construction plan. As of November 30, Jike has 401 Jichong stations, covering 100 cities nationwide, and has deployed nearly 2300 Jichong piles with a charging power of 360kW or more. It is expected that by the end of 2024, the number of Jichong stations will exceed 1000, and by the end of 2026, the cumulative stock of Jike Jichong piles will exceed 10,000, and each pile will be able to meet the charging needs of 800V platform vehicles.

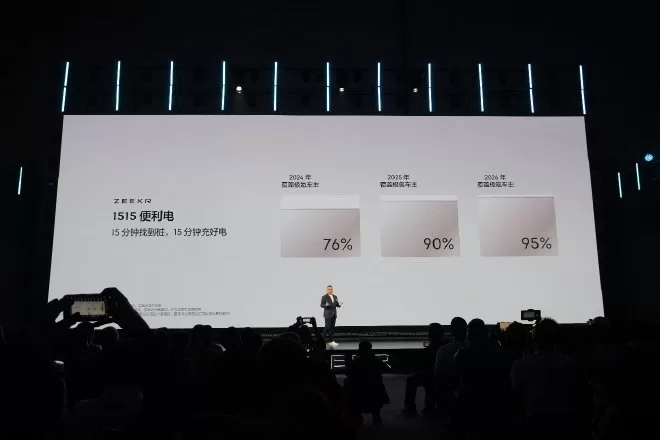

Currently, Jike has already partnered with 35 domestic high-quality public operators. After removing “zombie piles” and “faulty piles”, Jike’s charging map has already connected to over 610,000 “good piles” from three parties. Next year, the coverage of high-speed road charging piles will increase to over 95%. In order to facilitate daily charging for users, the Jike brand has launched the 1515 convenience electric service, which allows users to find a pile in 15 minutes and charge in 15 minutes, making charging as convenient as going to a convenience store. Jike’s “1515 convenience electric” will cover over 90% of Jike owners in the next three years, and will approach 100%, completely refreshing the super fast charging experience for users commuting in the city.

Earlier released Jike Wisdom Charging, also with the update push of Jike OS 5.1 system, has also been upgraded. This time, Jike Wisdom Charging has integrated the replenishment process into the in-vehicle intelligent ecosystem, achieving seamless in-vehicle intelligent charging from the vehicle end to the pile end through intelligent pile searching, intelligent battery heating, intelligent ground lock, and other functions. From finding a station to completing charging, users do not need to pick up their phones throughout the process, providing a better experience. At the end of the press conference, Jike brought good news to home charging users and released the Jike 20kW DC home charging pile. The official claims that a 100-degree battery can be fully charged in as little as 5 hours, and even a 140-degree large battery can be fully charged overnight, greatly facilitating home charging users and truly achieving worry-free replenishment.

Summary: As an electric vehicle user, battery life and recharging have always been unavoidable topics. This time, the Jike brand has released the technologically advanced Gold Brick battery, along with a matching Jichong network layout. In a sense, this has pushed the entire new energy vehicle market forward by a big step. Of course, the ones who will benefit are us, the consumers. This high-tech Gold Brick battery will be the first to be installed in the Jike 007 model. Jike’s self-developed Gold Brick battery and extensive Jichong recharging network bid farewell to range anxiety for users with hardcore technology. The release of the Gold Brick battery has brought the Jike brand into the 800V era and given the brand enough influence in the 800V platform field.