If it doesn’t say, no one will know that its 800V high-voltage platform technology leads the industry by 2-3 generations; if it doesn’t say, fast charging is one of the most efficient charging solutions; if it doesn’t say, public charging piles can be transformed into superchargers in seconds; if it doesn’t say, composite direct cooling technology can ensure the safety of charging; if it doesn’t say, intelligent pulse self-heating can make low-temperature charging in the northern winter worry-free. This is the BYD charging system that promotes very low-key in the charging field, but maintains a high “combat power”.

BYD’s charging system entered the game very early, just as it took the lead in the field of electric vehicles. From the 2008 220V household 2kW AC charging standard, BYD’s charging and energy replenishment has gone through years of experience. Now, with multiple charging measures in place at the vehicle end and the pile end, it has not only achieved a breakthrough in charging technology from 0 to 1, but also provided a reference model for national standard AC and DC charging standards with its self-developed home and public domain AC and DC charging technology. Today, it has become one of the first drafting units of China’s electric vehicle charging standards. From 2008 to 2023, BYD has spent 15 years solving the majority of pain points in electric vehicle charging and energy replenishment, and this field can be described as an “endless black hole”. The turnover of technology and the endless changes in demand are endless, but innovation has always been the driving force that BYD tirelessly pursues.

In the field of charging, it is not as easy to be remembered as in the passenger car field. In fact, since 2008, while introducing different charging technologies, it has been applied to a model, which is also the promise that BYD gives to consumers—release and mass production. Compared with the two independent sections of power supplementation and vehicle models, when BYD introduced its self-developed AC charging interface in 2008, it was targeted at the derivative model F3M of its hot-selling model F3.

Since 2008, BYD has installed various charging piles for technical applications outside the office building of Wang Chuanfu, including the eight-hole DC charging pile used by e6; the 10kW DC pile for e6; the 40kW AC pile for e5/e6; and now the 230kW dual-gun supercharging technology, which can replenish 350km in 15 minutes.

In fact, BYD’s charging and energy supplement does not separate the pile end and the vehicle end independently. At the “BYD Full Scene High-Efficiency Charging Technology Communication Conference” held in Beijing, we actually felt that BYD’s solution for charging and energy supplement is more aimed at a wide range of social scenes. For example, the dual-gun supercharging technology is based on the negotiation of public charging piles as the foundation, mobilizing millions of public fast charging pile resources. Currently, there are only 2% of public supercharging piles with a current exceeding 300A in China. Fast charging piles are widely popular, but supercharging piles are still extremely scarce. Instead of letting users fight for a small number of supercharging piles, it is better to fully utilize and turn public charging piles into supercharging piles in seconds.

This is BYD’s solution to the charging situation in our country, not only at the charging station, but also a charging innovation for the vehicle. It not only pioneered the dual-gun supercharging technology for passenger cars, but also utilized idle and negotiable public charging piles to form faster and more efficient charging power. Taking the Tang N7 as an example, the maximum power of the dual-gun supercharging can reach 230kW, and it can achieve a performance of charging 350 kilometers in 15 minutes on public fast charging piles.

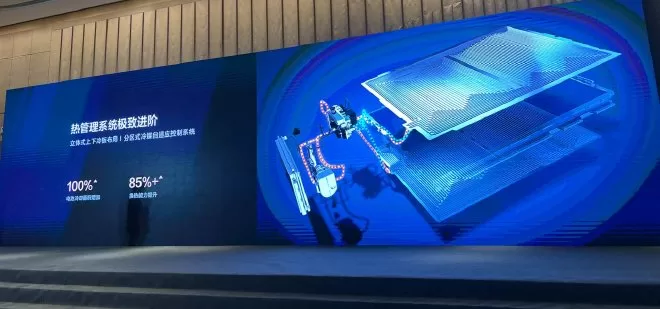

Obviously, this kind of integration can improve the energy supplement efficiency, but although the dual-gun can achieve the purpose of short-term and multi-energy supplement, another problem follows, which is the heat management of the battery. This involves BYD’s unique composite direct cooling technology, which is also a technological advancement for the vehicle end. BYD’s composite direct cooling technology is achieved through the design of direct cooling plates on both sides of the battery, as well as 2 sets of independent control systems for the refrigerant, compensatory flow channel design, and a 100% increase in battery cooling area and more than 85% increase in heat transfer capacity, providing users with supercharging safety and escort.

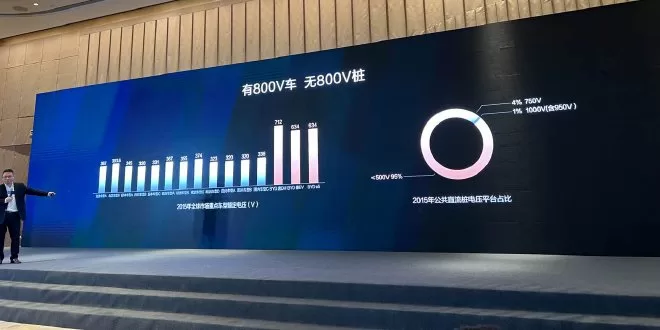

Upon closer inspection, it further confirms that BYD focuses on the integration of vehicles and charging systems in its energy replenishment system, which also includes an 800V high-voltage platform architecture. The meeting revealed BYD’s consideration of the 800V platform structure, that is, although high-voltage models have significantly increased the charging power of electric vehicles, currently, 95% of domestic charging piles are below 500V, which is not compatible with high-voltage models, not only affecting charging efficiency, but also increasing vehicle costs. To solve this problem, BYD’s boosting charging technology perfectly fulfills the mission of efficient charging compatibility, not only achieving vehicle-pile compatibility, but also fully adapting to all DC charging piles.

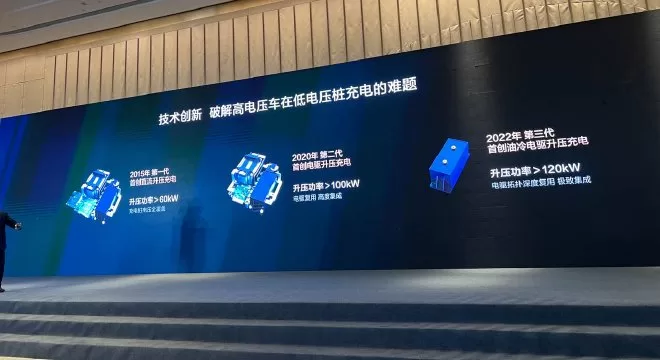

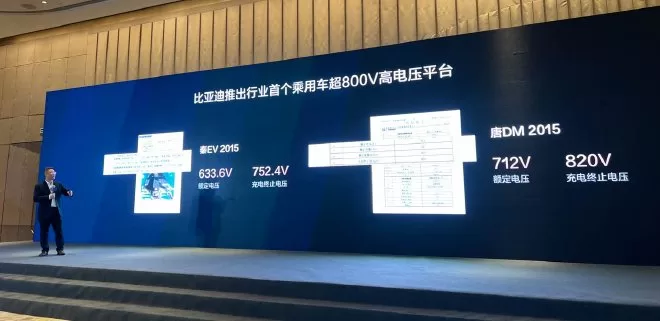

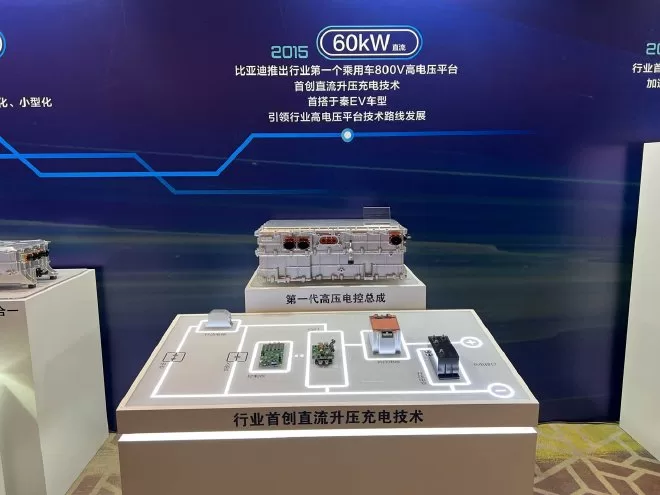

Despite this, BYD still has the capability to develop the 800V platform architecture. Many people still do not know that the global first 800V high-voltage platform was launched by BYD. This dates back to 2015, when BYD introduced the DC boost charging technology, which was the first 800V high-voltage platform for passenger cars. This technology pioneered DC boost charging and the first generation of high-voltage electronic control unit, first used in models such as Qin EV and Tang DM. This technology can achieve acceleration to 100km/h in as fast as 4 seconds, pure electric range of up to 450km, and fast charging power increased to 60kW, enhancing the overall user experience. BYD’s 800V high-voltage platform is 2-3 generations ahead of the industry.

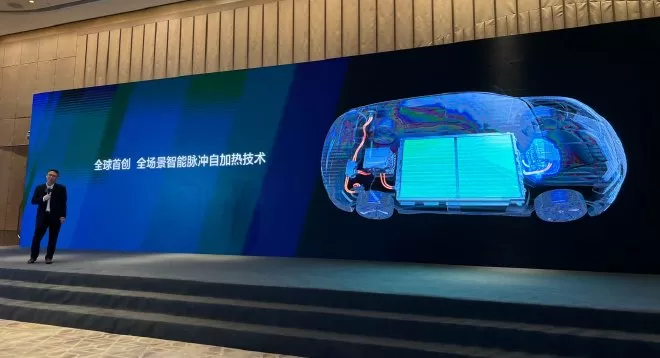

If the above are all BYD’s past in charging and replenishing energy, then for the future, on one hand, BYD is continuing to apply some technologies, and on the other hand, constantly innovating in replenishing energy, such as the full-scene intelligent pulse self-heating technology. This technology is mainly aimed at the needs of extreme cold fast charging. Simply put, it is to improve the charging efficiency in extreme cold winter.

This technology, exemplified by the N7, can heat the battery at a rate 230% faster than traditional methods in extreme cold conditions of -30℃. The full charge time is reduced by 30%, allowing users in the north to enjoy fast charging even in winter. The intelligent self-heating technology can be activated during parking and driving to ensure overall vehicle performance in very low temperatures.

In summary, BYD’s promotion of the charging system is not as high-profile as its passenger cars, but from the communication meeting, it is understood that BYD has developed a different charging route, which is integration. It not only integrates the vehicle and the charging pile, but also connects the entire charging chain of 800V+ boosting + dual guns + self-heating, creating a versatile charging system with BYD’s five globally pioneering charging technologies. It must be said that BYD is serious about playing with electricity, and it is sustainable, able to sustain continuous technological innovation.