The all-new BMW 5 Series long-wheelbase version, which made its global debut at the 2023 Guangzhou Auto Show, not only brings breakthrough design at this level, but also sets the benchmark for electric luxury with the introduction of the innovative all-electric BMW i5 for the first time in BMW 5 Series history. The benchmark luxury quality presented by the new car is the result of a strong development system and rigorous validation testing, as well as leading production processes and precise production concepts. Key points: 1. Before the mass production of the all-new BMW 5 Series long-wheelbase version, the production line needs to complete full-process trial production, which takes up to 1 year. 2. BMW creates a complete vehicle CUBING for every upcoming model to achieve almost zero tolerance for the standard body. 3. To optimize production line status, the body shop needs to produce over 1,000 trial vehicles and verify the strength of each weld and connection point, among other quality indicators. 4. The Shenyang production base has already implemented around 100 AI technologies. 5. The Da Dong factory stamping workshop has top-of-the-line six-axis servo presses and an industry-first AI intelligent quality inspection system. 6. The total length of the all-new BMW 5 Series long-wheelbase version’s adhesive coating far exceeds the industry average, not only optimizing the overall performance of the body, but also avoiding high later repair costs for users. Adhering to strict standards, only to deliver exceptional luxury quality.

Before the new BMW 5 Series long wheelbase version goes into production, it not only needs to pass “hellish” research and development verification tests, but the production line also needs to complete the full process trial production to ensure a high-quality driving experience for users. During the year-long trial production phase, BMW strictly controls the process, adopts industry-leading stringent standards, continuously improves the quality of parts and the entire vehicle, and optimizes the parameters of production equipment settings, ultimately achieving the full production standard of vehicle and process maturity. To ensure that the actual dimensions of the components match the design dimensions, BMW has created a standard vehicle CUBING for each upcoming model to be produced – a nearly zero tolerance standard body. CUBING is the embodiment of BMW’s “zero defect” concept, measuring the quality of components like an extremely precise ruler, even the slightest deviation in the dimensions or hole positions of the body parts cannot match. BMW not only spends a lot of money to create CUBING with aerospace-grade aluminum alloy materials and high-precision craftsmanship, but also keeps it in a constant temperature and humidity environment to avoid environmental impact on measurement accuracy.

To optimize the production line, the body shop needs to produce over 1,000 prototype vehicles and verify the strength of each weld and connection point. BMW will spare no expense in transporting prototype vehicles with no rework on welds and connection points to the German headquarters for dynamic corrosion resistance testing, driving the vehicles in various highly corrosive environments and submerging them in water, dismantling all components and inspecting for corrosion to ensure outstanding corrosion resistance. AI not only creates GPT, but also creates a high-quality intelligent luxury travel experience. The birthplace of the new BMW 5 Series long-wheelbase version – the BMW Shenyang production base is the vanguard of BMW’s iFACTORY overall production strategy, perfectly fitting the future production mode of “lean, green, digital”. Here, there are world-class leading processes, production standards that surpass the industry, and BMW’s commitment to high quality, all of which refine the ultimate luxury quality of the new BMW 5 Series long-wheelbase version. Currently, the Shenyang production base has implemented approximately 100 AI technologies. AI is empowering higher levels of quality control and consistency, making real-time process monitoring and instant data analysis possible.

The stamping workshop at the Dadong factory has the industry’s top six-axis servo tensile press, and also uses the industry’s first AI intelligent quality inspection system. The new BMW 5 Series long-wheelbase industrial camera records the surface condition of stamped parts at a high speed of 35 frames per second, taking over 2 million high-definition photos every day, with a total data volume equivalent to 1000 Blu-ray HD movies. The “never tired” AI intelligent quality inspection system, independently developed by BMW, not only inspects every part on the production line, but also can quickly complete the analysis of a single photo in just 0.01 seconds. The detection accuracy can gradually approach 100%, even making tiny gaps that are undetectable to the naked eye visible, ensuring that the parts enter the next process in the best condition.

After the completion of the white body, the all-new BMW 5 Series long-wheelbase version is taking shape and will be dressed in exquisite attire in the paint shop. The new BMW 5 Series long-wheelbase version offers a dazzling copper gray paint, with copper gold pearl particles ranging from 5-30 microns evenly distributed in the paint, shining brightly in the light and sunlight. To allow users to appreciate this beautiful color, the Dadong factory has adopted leading AI paint and AI clear coat polishing innovative technology to ensure that the paint surface of every BMW is uniformly delicate and flawless. With the support of AI technology, three robots of automatic optical inspection equipment will capture over 100,000 photos of each car and identify impurities, fibers, scratches, and other minor defects with a detection accuracy of 0.01 mm, marking the positions that need further adjustment on the paint surface with laser. Then, experienced production line workers will hand-polish the cars to the best state to ensure that the paint surface of every BMW meets the luxurious and high-quality standard. “Strongest on the surface” connecting technology, creating a solid body frame.

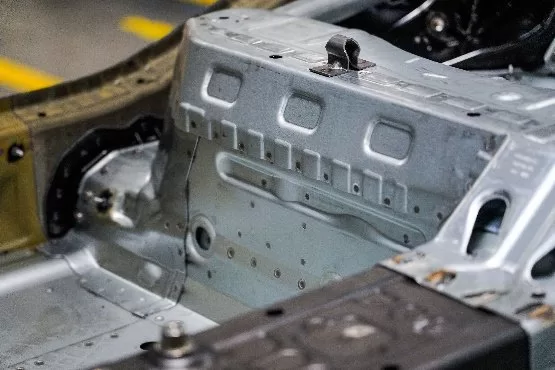

The complete and undamaged stamped parts enter the body shop, where they will be transformed into the all-new BMW 5 Series long-wheelbase steel frame in the highly automated robot “forest.” Here, 1,047 robots complete 19 world-class “strongest on earth” connection processes such as welding, riveting, screwing, and gluing, connecting over 430 components made of 30 different materials into a white body, with an automation rate of over 95%. Each robot and welding gun is linked to the Internet of Things platform and uses AI technology for data collection and analysis to ensure more precise body dimensions. If the thickness error of the body parts exceeds 0.1mm, it is considered unacceptable and requires rework adjustment.

As an important part of the body connection process, the adhesive coating process is not only suitable for the same materials, but also for different materials. It plays an indispensable role in the body strength, safety, corrosion resistance, shock absorption, noise reduction performance, and lightweight performance, and will also have a significant impact on the “luxury driving experience”. The total length of the adhesive coating of the new BMW 5 Series long-wheelbase version far exceeds the industry average, not only helping to optimize the overall performance of the body, but also avoiding high later maintenance costs for users. The new BMW 5 Series long-wheelbase version, created by a high standard research and development testing system and more advanced, more intelligent production processes, fully demonstrates the luxury heritage of BMW, and will bring users an excellent intelligent luxury travel experience with benchmark luxury quality.