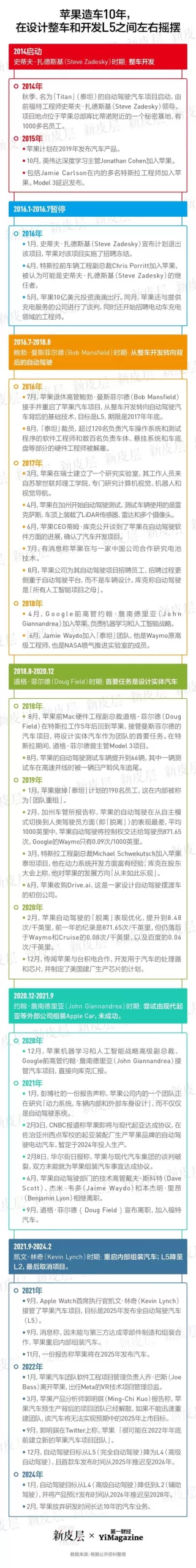

Ten years ago, Apple launched its ambitious car manufacturing plan, codenamed ‘Titan’. Despite some setbacks, in 2018, Apple had 66 cars testing on the roads. In 2020, Apple even negotiated with established car manufacturers like Hyundai and Kia, attempting to produce Apple-branded self-driving cars at Kia’s assembly plant in West Point, Georgia, with reports suggesting production could start in 2024. 2024 arrived, but Apple’s plan did not come to fruition. After several strategic adjustments, on February 28, Apple decided to stop manufacturing cars, gradually winding down the project. Following the cessation of car manufacturing, employees of the Apple car team will be reassigned to the artificial intelligence department, focusing on generative AI. Artificial intelligence and car manufacturing were not inherently contradictory. In 2018, Cook even referred to self-driving cars as the ‘mother of all AI projects’. However, in the business of self-driving cars, which combines both artificial intelligence and car manufacturing attributes, Apple failed – over the past 10 years, it neither produced a car nor successfully developed a self-driving system. From personal computers to smartphones, from music players to smartwatches, from tablets to headsets, Apple has successfully redefined multiple markets. Self-driving cars were the first boundary that Apple touched under the ‘redefining…’ mode. Strategically, choosing generative AI is a better option. As long as Apple can make a comeback in the AI field, it still has the potential to launch its own brand of cars in the future. Currently, Apple has not released any models in the generative AI field, lagging behind both startups like OpenAI and Anthropic, as well as big companies like Microsoft, Google, and Meta. After the news of stopping car manufacturing and focusing on generative AI came out, Apple’s stock price not only did not drop but actually rose slightly. However, to explain why Apple failed in the car manufacturing business, one must return to the strategies it adopted in the field – striving for the best hardware and the most advanced self-driving system. This ‘aim high’ strategy has been successful in many of Apple’s products, but it failed in the car project. The following car manufacturing process demonstrates why this strategy failed: ‘2014-2016’ Zadesky: Both hardware and L5.

– Background: Led the Titan project, with a background in mechanical engineering, worked as an engineer at Ford for 3 years, joined Apple in 1999 and participated in the design and development of iPod and iPhone. – Approach: Starting from scratch, focusing on the development of the entire vehicle, including hardware and software. – Results and setbacks: Zadesky assembled a team of 1000 experts covering software engineers, hardware engineers, and automotive design and manufacturing, to develop all aspects from software to hardware, from autonomous driving systems, battery technology to vehicle design and manufacturing. However, due to manufacturing constraints, Apple was forced to consider partnering with more mature car manufacturers such as BMW, using BMW’s electric i3 model as a development platform, but BMW’s willingness to cooperate was not strong, and the cooperation broke down due to leadership and ownership issues. Just as the project was getting started, Zadesky clashed with Apple’s design chief Jony Ive, who wanted to develop a semi-autonomous driving capable car, while Zadesky wanted to focus on software and develop a fully autonomous car without a steering wheel. In January 2016, Zadesky left Apple for personal reasons, and Jony Ive implemented a hiring freeze on the team. – ‘2016-2018’ Bob Mansfield: Focused on autonomous driving, loss of hardware personnel.

– Background: Former Apple executive, joined in 1999, led hardware engineering team for Mac, iPhone, iPad, and special projects. – Strategy: Pause vehicle development, focus on autonomous driving software. – Achievements and failures: Under Mansfield’s leadership, Apple established research lab in Switzerland for computer vision, robotics, and visual navigation. In 2017, Apple was granted permission to test autonomous driving technology on public roads in California. First official test used Lexus vehicle, then partnered with Hertz for further testing. Also researching battery technology, signed research agreement with CATL.

Mansfield shifts focus to autonomous driving platform, leading to exodus of vehicle control researchers. 17 employees specializing in brake, suspension, and other car systems reportedly jumped ship to autonomous driving company Zoox in the same month. Doug Field, who left Apple for 5 years, returned to the company and Mansfield was able to retire. Doug Field: Back to automotive hardware development 2018-2020.

– Background: Former CTO of Adobe Systems, joined Apple to lead projects related to Apple Watch and its health-related functions. – Strategy: Restart vehicle development and adjust the target from L5 to L4. – Results and setbacks: After Doug Field took over the Titan project, Apple restarted the automotive R&D lab and began contacting global automotive parts suppliers, inquiring about parts and attempting to build its own car, planning to release it in 2025. However, 3 months later, Apple shifted its focus from creating a fully autonomous vehicle to developing a car with autonomous driving assistance features, similar to those offered by Tesla, Ford, and other car companies. – In early 2024, Apple further delayed the car release to 2028 and lowered the autonomous driving specification from L4 to L2+, only allowing automatic driving on highways, with a price of less than $100,000, but this may not provide the profit margin that Apple products typically enjoy. – In the matter of building cars, Apple’s relationship with Tesla is somewhat delicate. – In August 2015, reports indicated that Jamie Carlson, a senior engineer at Tesla, and at least six other Tesla employees with experience in developing autonomous vehicles, joined Apple, which to some extent affected Tesla’s product roadmap. There was a belief at the time that the delayed release of the Model 3 was due to the departure of a large number of Tesla employees to Apple. – In 2018, Doug Field, who was in charge of the Tesla Model 3 project, also joined Apple and became the leader of the Titan team, making the design of a physical car a top priority. The following year, Apple dismissed over 200 employees from the Titan project under the guise of ‘team restructuring’. – At the end of December 2020, Tesla CEO Elon Musk tweeted that when he was under pressure during the development of the Tesla Model 3, he had attempted to contact Apple to discuss the possibility of selling Tesla to the company. At the time, Musk planned to sell for approximately $60 billion, only 1/10 of Tesla’s current market value. However, Apple CEO Tim Cook declined the invitation to discuss this.