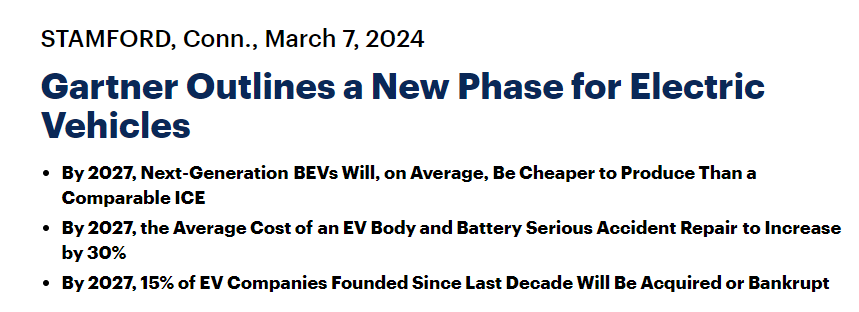

On Thursday, global information technology research and advisory company Gartner released its latest forecast, showing that by 2027, the average production cost of pure electric vehicles will be lower than that of similar internal combustion engine vehicles as manufacturing methods continue to lower production costs. Gartner said that in 2024, automakers will continue to adapt to the shift brought by software and electrification, paving the way for a new phase in the electric vehicle industry.

Pedro Pacheco, Vice President of Research, wrote that new OEM manufacturers are eager to redefine the automotive industry. They bring new innovations that simplify production costs, such as centralized vehicle architecture and the introduction of “integrated die casting” to reduce manufacturing costs and assembly time. Integrated die casting refers to the manufacturing technology that integrates nearly a hundred scattered components into a large-sized part using a large-tonnage die-casting machine, abandoning traditional automotive stamping and welding processes. Due to breakthroughs in integrated die casting technology, Tesla has significantly increased production efficiency and greatly shortened the development cycle of new cars. Pacheco explained that traditional car manufacturers have no choice but to adopt these innovations to survive. Gartner predicts that 2027 will be a crucial year for electric vehicles. By then, the average production cost of the next generation of pure electric vehicles will be lower than that of similar internal combustion engine vehicles. With the continuous disruptive changes from equipment manufacturers, the decline in BEV production costs will be much faster than battery costs. Pacheco stated that this means pure electric vehicles will reach the breakeven point with internal combustion engine costs faster than initially expected. However, this will significantly increase some maintenance costs of pure electric vehicles. Gartner predicts that by 2027, the average cost of body and battery repair for BEVs in serious accidents will increase by 30%. Taking integrated die casting as an example, this process significantly reduces the number of body parts and improves the tensile stiffness of the chassis. “But ‘one loss is a loss for all’, and if it is damaged, the entire large casting needs to be replaced, which is equivalent to returning to the factory for reassembly, at a high cost. Gartner believes that the process of rapidly reducing BEV production costs should not come at the expense of increased maintenance costs, as high maintenance costs may cause strong consumer aversion. The organization recommends that new methods for producing BEVs must be deployed together with processes to ensure low maintenance costs. In January of this year, Hertz, once Tesla’s largest customer, plans to sell one-third of its electric vehicles in the United States and reinvest in fuel vehicles. At that time, the CEO said, ‘Most of our vehicle categories have achieved increased profit margins, with the only exception being electric vehicles, because they have high maintenance costs.’ In addition, Gartner also predicts that by 2027, 15% of the electric vehicle companies established in the past 10 years will be acquired or go bankrupt. Pacheco added, ‘This does not mean that the electric vehicle industry is collapsing, it is just entering a new stage, and companies with good products and good services will prevail over others.’ Gartner expects electric vehicle shipments to reach 18.4 million units in 2024 and 20.6 million units in 2025. However, the market is already transitioning from a ‘gold rush’ to ‘survival of the fittest.’ Pacheco commented that some startups are still heavily reliant on external funding, making them particularly vulnerable when facing market challenges.” He also mentioned that some countries are gradually canceling related incentive measures, and the challenges facing businesses will continue to increase day by day.

Elon Musk previously commented on Rivian’s situation, stating that they need to significantly reduce costs and have their executive team live in the factory, otherwise the company will perish. He also mentioned that while their product design is good, the real challenge for car companies is achieving mass production and generating positive cash flow. As for Lucid, which was once dubbed a “Tesla killer,” Musk commented that they are currently relying on “daddy from Saudi Arabia” to survive.