For new energy vehicles, safety is more important than price. On March 25, Geely’s Galaxy E8 successfully passed a 20-ton out-of-control heavy truck crash test, once again proving its vehicle safety standards. In the experiment, a Galaxy E8 test vehicle, in a stationary state, was hit on the left side by a 10-ton heavy truck at a vertical angle and a speed of 30km/h. After the impact, the Galaxy E8 test vehicle experienced displacement and collided with the right side of another stationary 10-ton heavy truck in the same direction, with an energy impact 3.3 times higher than the national standard.

After the collision, the Geely Yuanjing E8 passenger cabin structure remained intact, providing sufficient survival space for passengers. The A, B, and C pillars did not experience structural failure. The seat mounting points and seat frames showed no obvious deformation. The front seat belt pretensioners deployed, and the seat belts did not fail. The side airbags and side curtain airbags deployed in a timely manner.

For new energy vehicles, battery safety is the most dangerous after a collision. The battery pack is located under the chassis of the vehicle, closest to the side of the vehicle. The safety protection is often the weakest, relying on the thickness of the door sill beam to support and absorb collision energy. In the event of a collision with a 20-ton out-of-control heavy truck, the Geely Galaxy E8 quickly shut down the high voltage, with no leakage of electrolyte, and the battery pack did not catch fire, explode, or smoke, ensuring battery safety. At the same time, the hazard lights were turned on in a timely manner, the door handles automatically popped out, and the E-Call emergency rescue function was activated, automatically dialing with a human customer service representative. Geely Galaxy E8 undoubtedly scored high in such collision results, relying on the new generation of God Shield battery safety system, star armor cage body, “ten-grid” battery anti-collision compartment, four longitudinal and four transverse frame beams, “dragonfly” power transmission structure and other patented designs. The Galaxy E8 passed this challenge with high standards, which has always been Geely’s consideration and commitment to the safety of new energy vehicles. For new energy vehicles, and even pure electric vehicles, battery safety is the bottom line and the foundation. The Galaxy E8 is equipped with a new generation of God Shield battery safety system, ensuring battery safety from the cell layer, PACK layer, architecture layer, and safety testing layer in four dimensions. In terms of battery core, by improving the electrolyte formula, the reaction heat between solid-liquid interfaces is effectively reduced, significantly improving the thermal safety of the battery. The gradient structure design of the battery core electrode coating enables high ion diffusion rate and high electron conduction rate, providing excellent fast charging and high power performance. In addition, based on comprehensive extreme conditions, the Shield Battery Safety System has undergone more than 100 basic tests at the battery pack level, including simulated collisions, mechanical impacts, water immersion safety, humidity cycling, salt spray, and heat diffusion, providing assurance for the safety of new energy vehicles. In the event of an unforeseen thermal runaway incident, the Shield Battery Safety System can ensure early warning at both the vehicle end and the cloud end, minimizing the risk of fire. After triggering a thermal runaway of the battery core, the surface temperature of adjacent battery cores is only half of the temperature of the runaway core, and within 24 hours the battery does not catch fire or explode, the smoke concentration in the vehicle is 0, providing sufficient time for personnel to escape and for firefighting rescue. In addition to the efficient thermal management design of the battery system, the Shield Battery Safety System uses intelligent safety standard design, providing all-weather safety monitoring at both the vehicle end and the cloud end. The intelligent battery temperature control technology covers all scenarios, intelligently identifies charging and discharging environments, matches charging piles intelligently, identifies potential charging risks in advance, and cuts off charging connections in a timely manner to protect battery safety.

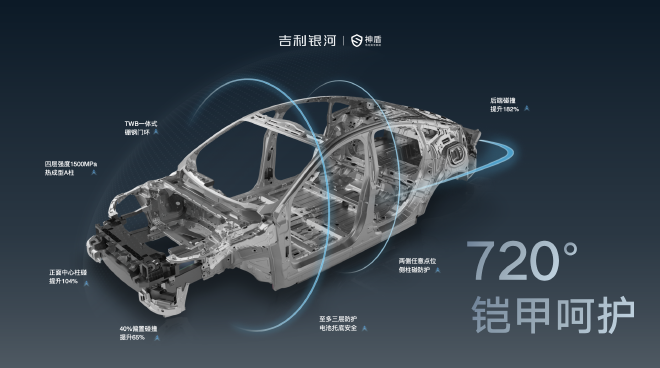

Outside the battery, the vehicle body is another important protection for the safety of passengers. The Geely Xingjia cage body structure is used, with a high strength steel and aluminum alloy utilization rate of 80.3%, and a body torsion stiffness of 41000Nm/deg. In the event of a collision, the cage body structure can distribute and transmit the force throughout the entire body, avoiding excessive local stress and reducing the risk of collision.

In addition, the Geely Galaxy E8 features a “ten-grid” battery anti-collision compartment on the side, with three irregular anti-collision compartments inside the door threshold anti-collision beam, made of aerospace aluminum alloy with a thickness of 163mm, the highest in its class. It absorbs energy instead of the battery, meets comprehensive side pillar collision safety tests, with a maximum intrusion of 12.5mm, ensuring the safety of the battery and passengers. Geely’s multiple pursuits and guarantees for safety allow the Geely Galaxy E8 to perform excellently in rigorous collision tests, indicating that Geely is building its own intelligent safety fortress. Safety is the foundation of cars, an eternal principle in the era of fuel vehicles and in the era of new energy vehicles. Geely has always been refreshing its safety standards and creating a series of new standards for the industry.