China’s penetration rate of new energy vehicles exceeds 51%. This is a happy achievement. Compared to imported and joint venture brands, domestic brands thrive in the era of new energy vehicles. China has become a global leader in new energy vehicle technology. As the number of new energy vehicles rises, safety concerns grow. New energy vehicles face more risks in accidents due to their power batteries. In response, the government has set strict standards for testing these vehicles. Major new energy vehicle brands implement testing standards that surpass national requirements. They prioritize consumer safety. Today, we visit the 2024 Technology Open Day of the Qichen brand to explore their advancements in battery safety.

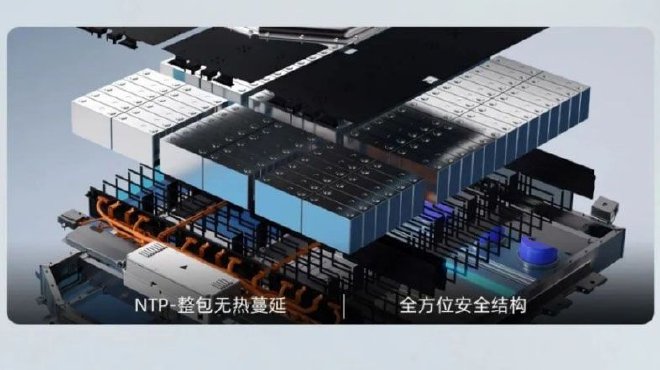

Last year, the Qichen brand introduced the concept of “integrated vehicle and battery safety.” Qichen believes battery safety involves more than just the battery. It requires considering vehicle safety and user scenarios. They aim to create a comprehensive battery safety system. Qichen employs a five-dimensional safety protection approach through cell design, BMS, battery packs, the vehicle, and cloud services. This ensures users feel secure while driving. Qichen focuses on technology development. It leverages the Dongfeng Nissan Technical Center to advance plug-in hybrid, pure electric, and hydrogen energy technologies simultaneously. The brand concentrates on smart cockpits, intelligent driving, electronic architecture, and software, achieving a comprehensive layout in new energy technology. In the pure electric sector, Qichen presents three key technology areas: the Vita native electric platform, V-Joy intelligent space, and Luban battery. The Vita platform caters to target user needs, delivering high-efficiency pure electric performance. It boasts over 91% operational efficiency and space utilization, both leading in the industry. V-Joy intelligent space uses a self-developed SOA electronic architecture to offer customizable smart mobility experiences. The Luban battery is a crucial element of Qichen’s “integrated vehicle and battery safety” philosophy.

To ensure excellent battery performance and safety, Luban batteries undergo rigorous testing before meeting users. Tests include submersion, corrosion, collision, fire, puncture, and simulated fast charging and discharging. First, let’s discuss the battery structure. The vehicle body uses high-strength steel to resist deformation during collisions. The battery compartment follows the same principle. Luban’s battery compartment features a 1.8GPa diamond shield, an integrated aerospace-grade skeleton, 360° crumple protection, and industry-leading dual-layer armor at the bottom. This comprehensive structure enhances the battery’s safety. During real vehicle testing, we conducted bottoming tests with obstacles of 210mm and 220mm heights. The vehicle passed at a speed of 50 km/h. The bottom battery compartment showed no significant deformation, which was quite surprising.

A short circuit in a battery raises internal temperatures. This can easily cause fires and explosions. Most short circuits happen when external impacts or sharp objects penetrate the battery. In the Luban battery test, researchers conducted a puncture test. They used a steel needle to pierce the center of the battery. The battery short-circuited and produced a lot of smoke. After 20 minutes, the battery did not catch fire, showing excellent performance.

In a real-world scenario, the Qichen VX6, equipped with Luban batteries, crossed a 50-meter stretch of “Fire Road” at 10 km/h. The test put the battery to the ultimate test. The vehicle moved slowly but remained unharmed. This success stems from the clever design of high-safety cells, high-integration blocks, and independent exhaust channels. The technology includes 360° flame-retardant protection and an intelligent constant-temperature thermal management system. These features effectively mitigated the risk of thermal runaway in the battery cells.

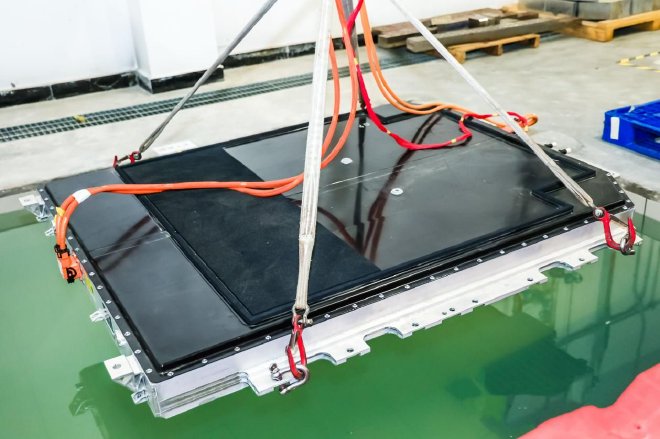

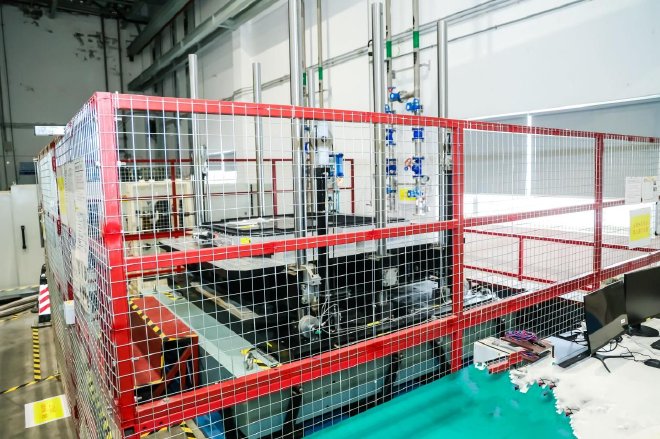

The battery of pure electric new energy vehicles sits at the bottom of the chassis. In extreme weather like rain or snow, the battery can soak in water for long periods. Thus, waterproof performance is crucial. Luban batteries feature a double-layer sealing design. They achieve waterproof ratings of IPX7 and IPX9K. They withstand immersion in 1 meter of water for 24 hours without water ingress.

In a real car scenario, the vehicle travels at 10 kilometers per hour. It moves through a pool with 70 centimeters of water. The water level reaches halfway up the door. The chassis completely submerges. After leaving the puddle, the vehicle continues to drive.

In addition, Luban batteries undergo high-altitude drops, collision impacts, and repeated simulations of extreme cold and heat during charging and discharging. These tests assess the battery’s safety and durability.