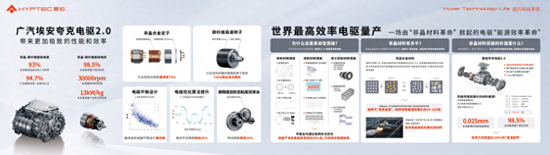

On August 23, GAC Aion’s Quark Electric Drive 2.0 achieved mass production with a focus on amorphous alloy breakthroughs at Ruipai Power Technology. It boasts the world’s highest mass production motor efficiency at 98.5%. It also has the highest power density at 13 kW/kg and the highest motor speed at 30,000 rpm.

Academician Zhu Meifang, Professor Yu Muhuo, and Professor Yao Kefu, along with other industry experts, attended the event. They witnessed a historic moment in China’s new energy technology. The technology achieved breakthrough progress.

Reports indicate that GAC Aion will first equip the Quark Electric Drive 2.0 in the Haobo brand series. This will increase the range by 50 km. Every kilowatt-hour will go further. First, let’s focus on the Quark Electric Drive 2.0’s first global achievement: production motor efficiency. The motor efficiency reaches 98.5%. This figure approaches the physical limit of 100% room temperature superconductivity, leaving many competitors far behind.

Next is the second global first—motor power density. Quark Electric Drive 2.0 achieves an astonishing 13kW/kg. This figure nearly doubles the industry average. Now, let’s look at the third global first—motor speed. Quark Electric Drive 2.0 reaches 30,000 rpm. It surpasses many competitors and enhances its power performance.

In the past, electric motors reached a maximum efficiency of 98%. This approach neared the physical limit. Improving efficiency by 0.1% posed a global challenge. The Quark Electric Drive 2.0 uses amorphous alloy. This material is the most advanced soft magnetic material today. It is known as “liquid metal.” It serves as a black technology material for aircraft carriers. It magnetizes easily. Its magnetic permeability is 20 to 100 times that of standard silicon steel sheets. Additionally, its thickness is only 1/4 that of standard A4 paper. This thickness is 90% less than traditional silicon steel. Iron loss decreases by over 50%. Therefore, electric motors made from this amorphous alloy can approach 100% efficiency. They ultimately achieve a breakthrough in limits.

The arrival of GAC Aion Quark Electric Drive 2.0 sparks an energy efficiency revolution. This is not just theoretical; it is a real mass production achievement. Quark Electric Drive 2.0 excels in efficiency, power, and speed. It offers users longer range. It also helps the industry overcome material bottlenecks and supports the national dual carbon goals.

Quark Electric Drive 2.0 has rolled off the production line. Users enjoy longer ranges. Pure electric users can increase their range by 50 km without adding batteries. Four-wheel drive users gain high performance with a range equal to that of two-wheel drive. This achieves a balance between performance and range. Future range-extender users can also enjoy an increase of 150 km without a large fuel tank. This breakthrough in material technology marks a significant achievement. The team developed new material patents, advancing from design to structure. They achieved the world’s first mass production of amorphous alloy electric drives. This will elevate the electric drive industry. Quark Electric Drive 2.0 also supports national carbon neutrality goals. China currently has 24.72 million electric vehicles. If each vehicle travels 10,000 km annually, the same energy consumption with amorphous alloy electric drives can cover 18.5 billion kilometers. This equals 4.62 million trips around the Earth’s equator. It can save 90 billion kilowatt-hours of electricity annually, equivalent to the total annual output of the Three Gorges Dam.

GAC Aion Quark Electric Drive 2.0 will first equip the Haobai brand series. It offers longer range. This eases range anxiety for electric vehicle users.