On August 23, 2024, the China Automotive Technology Research Center announced the winners of the “2024 China’s Top Ten Chassis” award. This award is a joint effort with industry authorities and universities. The Wuling Xingguang S, built on the Tianyu D platform, won the title of “2024 China’s Top Ten Chassis.”

The “2024 China Top Ten Chassis” selection underwent multiple rounds of strict screening, including public voting, online preliminary evaluations, and live vehicle presentations. Industry experts, media representatives, and user representatives participated in the live presentations to ensure ecological fairness. The selection featured both dynamic and static evaluations to verify the chassis’s overall technical level. This dual approach assessed the evaluation system’s scientific rigor through objective and subjective dimensions. Ultimately, the selection identified the top ten award-winning models for the year.

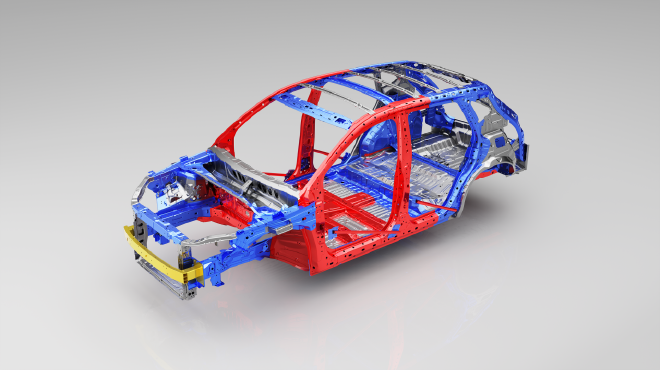

The Wuling Xingguang S features a high-strength steel body structure. It uses a full-frame front subframe energy absorption technology, which enhances body strength. The coverage of high-strength steel in structural components exceeds 82.5%. This increases the vehicle’s resistance to deformation and improves safety. Additionally, the Wuling Xingguang S employs a comprehensive simulation and testing verification system. It passes tests for 60 km/h road conditions without loosening, deformation, or cracking. The agile braking system achieves an emergency braking distance of less than 38 meters at 100 km/h. It builds pressure within 0.15 seconds, significantly improving brake response. The vehicle also includes a 0.5g backup braking deceleration for added safety. The ESC electronic stability control system integrates 12 sub-functions, enhancing stability and safety, providing invisible protection for users.

The Wuling Xingguang S passed over 2,200 hours of durability testing. This included 24-channel vehicle tests, 12-channel subsystem tests, four-column tests, and component-level tests. The vehicle also completed 33 durability tests on high-precision user scenarios. It underwent extreme temperature tests from -40 to +40 degrees. Additionally, it faced over 500,000 kilometers of high-mileage tests.

The Wuling Xingguang S features a mixed design of high-strength steel and aluminum in its chassis. The lightweight, crash-resistant design reduces the unsprung mass. This multi-level topology technology combines lightweight and conceptual lightweight designs to cut weight by 15 kg compared to similar vehicles. To reduce drag, the Wuling Xingguang S uses a caliper drag force as low as 0.9 N·m and a low rolling resistance bearing under 0.8 N·m. This setup decreases driving resistance and increases the vehicle’s range by 10 km compared to conventional solutions. Additionally, the excellent energy flow management system lowers system resistance by 2% compared to similar vehicles.

The chassis hardware features independent front and rear suspensions. It uses a decoupled design for dynamic and static stiffness based on scenarios. This boosts energy absorption efficiency by 15%. Vibration filtering improves significantly, enhancing ride comfort. The MacPherson independent front suspension employs a vulcanized integrated bushing in the front stabilizer. This eliminates noise risks in low temperatures and enhances NVH performance. Additionally, the chassis adopts a lightweight design. The control arms use high-strength steel, while the steering knuckles are made of aluminum alloy. This reduces unsprung mass, improving comfort and handling. The rear suspension features an E-type multi-link independent setup. It connects to the body with 100% flexibility. The front and rear suspensions connect to the body at 12 key points, all using flexible connections. The soft connection ratio reaches 86%. This improves NVH performance and enhances passenger comfort.