“Integration of vehicle and battery ensures true safety for electric cars.” Safety issues in new energy vehicles have become a focal point for the industry. At the recent 2024 World Power Battery Conference, CATL Chairman Zeng Yuqun emphasized, “The power battery industry must enter a high-standard development phase.” He prioritized high safety as essential for the industry’s sustainable development. Currently, some power batteries lack adequate safety measures. “In 2023, the fire incidence rate for new energy vehicles was 0.96 per ten thousand. The number of new energy vehicles in China exceeds 25 million, with billions of battery cells in use. If safety issues remain unresolved, the consequences will be catastrophic.” Zeng Yuqun believes, “Battery safety is a systemic project that requires improved standards in material thermal stability.” He called for the establishment of absolute safety standards, urging, “Set aside competition and prioritize consumer safety.”

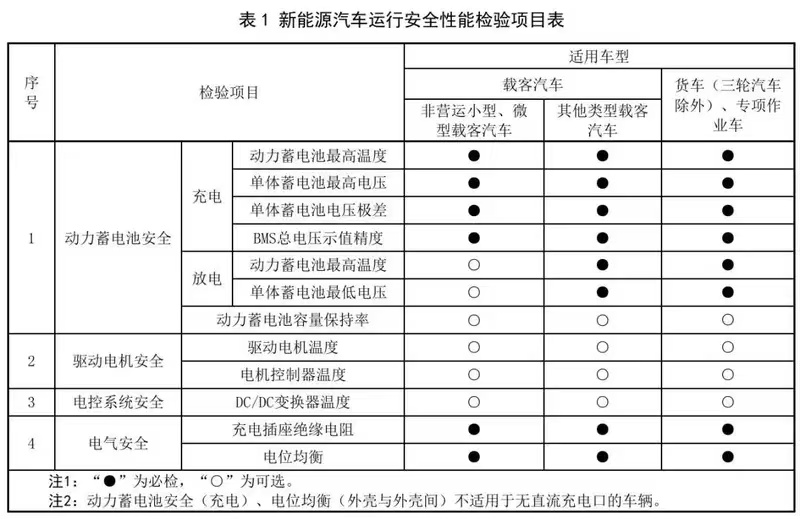

Zeng Yuqun shares similar concerns. The recently released “Safety Performance Inspection Regulations for New Energy Vehicles” will take effect on March 1, 2025. These regulations strengthen testing standards for new energy vehicles. They require safety inspections of power batteries and electrical systems. The regulations also cover safety checks for drive motors and electric control systems. They apply to all operational pure electric and plug-in hybrid vehicles. This is China’s first safety inspection standard specifically for new energy vehicles. Previously, new energy vehicles followed the same inspection frequency as fuel vehicles, starting with inspections every two years after six years, and annually after ten years. Unlike fuel vehicles, new energy vehicles face many safety issues. A blogger reported that for new energy vehicles over six years old, the random inspection pass rate is only 10%. Though this data is unofficial, it highlights serious safety problems in the new energy vehicle sector. To prove the safety of their new energy vehicles, many car manufacturers focus on battery packs and management systems. For example, BYD claims its ternary lithium batteries undergo rigorous safety tests and certifications, ensuring safety under extreme conditions like punctures, fires, and short circuits. BYD’s battery management system ensures safe operation across various scenarios. This guarantees the safety of BYD batteries. Zeekr recently launched its second-generation battery, featuring eight thermal safety technologies. It passed overpressure puncture tests, 240-second fire tests, and six extreme condition tests. The AI BMS technology improves battery charge estimation accuracy and identifies risks early, extending battery life. Single cells can pass puncture tests. Entire battery packs can withstand crushing and immersion tests. Brands like BYD and Zeekr now extend safety to the entire three-electric system. This advancement significantly improves the overall safety of new energy vehicles. However, from a safety perspective, this is still insufficient. We must integrate the three-electric system with the whole vehicle. We need a comprehensive safety concept. Every component, from individual cells to battery packs and entire vehicles, must be safe for consumer confidence. Recently, Dongfeng Nissan’s Venucia brand introduced the concept of vehicle-battery integration as true safety, emphasizing the safety of new energy vehicles from a whole-vehicle perspective. To verify the safety of its electric vehicles, Qichen showcased its core design. This design integrates the “three ends” and “five dimensions.” The “three ends” include the cloud, vehicle, and battery. The “five dimensions” cover the cloud, vehicle, battery pack, BMS, and cell. Qichen also tested the VX6 against water, fire, and scraping challenges.

The Qichen VX6 video of fire testing drew attention from many car enthusiasts. Many questioned the logic of setting a whole car on fire for testing. After all, an undamaged battery pack is hard to ignite from the outside. Using external fire to prove no risk of spontaneous combustion does not demonstrate true capability. Looking solely at the external fire test, Qichen’s approach seems flawed. However, within the context of their entire testing system, it reveals some insights. The Qichen Luban battery has passed rigorous tests, including puncture, external fire, drop impact, and seawater immersion. It demonstrates fire resistance and explosion prevention. Testing the whole vehicle in water, fire, and scraping challenges adds complexity. From a safety perspective, electric vehicles must ensure that key components like cells and battery packs do not catch fire or explode. They must also guarantee consumer safety during use. Beyond water, fire, and scraping tests, the vehicle must remain safe amid changing environments. Each consumer has different habits and usage scenarios, so it is vital to eliminate all spontaneous combustion risks, not just from the battery pack. It is not enough to say an electric vehicle is safe if the battery pack does not ignite. True safety requires both the vehicle and battery to be secure.