At the Changan Mazda MAZDA EZ-6 launch, the successful “truck lateral squeeze and scraping challenge” showcased Mazda’s safety expertise. Recently, Changan Mazda and Beijing Institute of Technology’s Shenzhen Automotive Research Institute live-streamed the vehicle disassembly from the crash test. Let’s take a closer look.

The side of the vehicle is its weakest part. It lacks the long engine compartment at the front that absorbs impact. Behind the doors are the passengers. Therefore, side collisions pose a greater risk of injury or death to occupants.

The EZ-6 simulates a scenario where a speeding truck strikes a car’s side. This impact causes the car to slide sideways. The battery pack hits the curb. Then, the car collides with a wall. This creates a series of collisions.

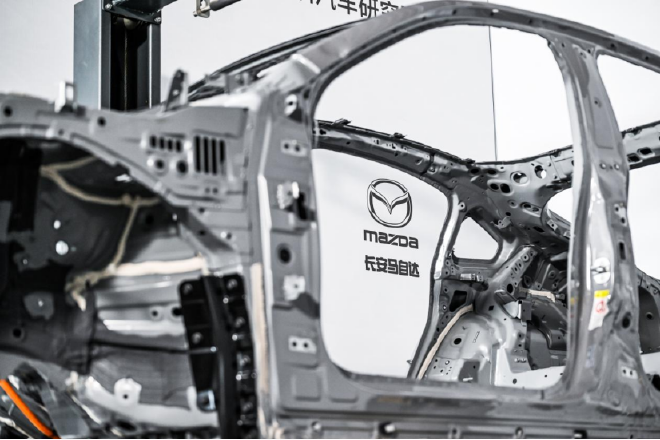

The live broadcast shows that the passenger cabin structure remains intact. Passengers have ample survival space. The A, B, and C pillars did not fail structurally. The seat mounting points and seat frames show no significant deformation. The airbags protect passengers promptly and effectively. The EZ-6 quickly cuts high voltage after the collision. The battery pack did not smoke, catch fire, or explode. Only complete disassembly reveals the EZ-6’s safety architecture. During the side impact, the vehicle’s lower crossbeam, doors, B pillar, and roof absorbed most of the impact energy. Key areas of focus include the hardness of the high-strength steel and the safety design of the body structure.

The EZ-6 features a cage structure with 7 horizontal and 5 vertical beams. It quickly disperses and transmits impact forces during side collisions. This design prevents excessive stress at a single point. Additionally, the EZ-6 roof includes a 2,000 MPa crossbeam reinforcement. The doors contain six 1,500 MPa crash-resistant steel beams. For passive safety, the EZ-6 comes standard with nine airbags. These include driver and passenger airbags, front side airbags, side curtains, front far-end airbags, and rear airbags. The side curtains extend 2 meters. The passenger airbag has a capacity of 120 liters, and the front far-end airbag has 43 liters. The dual pre-tensioners and dynamic latch seatbelts protect passengers during a collision.

Dong Bo, the safety officer of Chang’an Mazda, introduced the safety design of the EZ-6 battery pack. First, the high-rigidity protective shell of the Qi Ji battery prevented significant damage to the battery pack structure. The battery’s fastening points showed no major bolt deformation or tearing after impact. The bottom of the battery experienced only slight friction.

Most impact force gets absorbed by the car’s crossbeam and the reinforced battery pack. Therefore, the EZ-6’s battery pack does not deform. The overall structure of the battery remains intact. This prevents smoke or fire caused by battery structure failure. The EZ-6 features the Qiji battery. It includes digital battery management technology. This technology allows for 24/7 monitoring. It achieves a warning accuracy rate of 99%. The digital temperature control technology ensures safety. Even if the cell experiences thermal runaway, the entire pack remains stable. It avoids fire or self-ignition for 30 minutes after thermal runaway, ensuring passenger safety.