On November 18, 2024, BYD celebrated its 30th anniversary at the BYD Industrial Park in Shenzhen. BYD has existed for 30 years, but it has only built cars for just over 20 years. Twenty years is a short time for a large industrial company. In this time, BYD transformed from a novice in car manufacturing to the world’s leading new energy vehicle company. On that day, the 10 millionth new energy vehicle rolled off the production line.

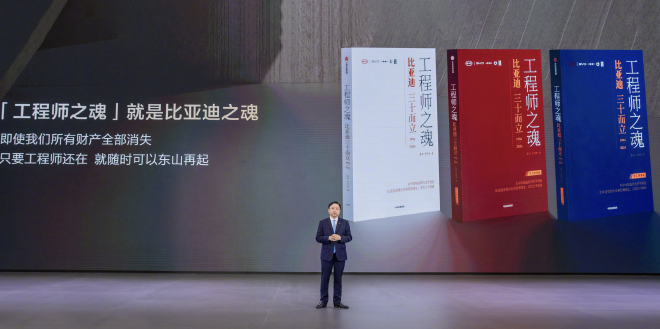

In 2023, BYD entered the top 10 global car manufacturers for the first time. This year, it expects to make a significant leap, aiming for fifth or sixth place. More importantly, its 900,000 employees show high morale and enthusiasm. They embody a proactive mindset, unlike the current leader focused on maintaining its position. This is a dream come true. “Build your dreams,” a phrase initially coined for effect, now seems like a remarkable prophecy. In just five years, BYD has rapidly risen in the market. It clearly holds strategic initiative, transforming the situation to its advantage. This power is unprecedented. Simply put, BYD has become a player capable of influencing the automotive industry landscape. Many wonder about BYD’s secret to success. Chairman Wang Chuanfu mentioned in a speech that faith in technology and a willingness to dream and act are BYD’s business secrets. This may sound vague. People often seek insights on business tactics and strategic decisions. However, this truly reflects BYD’s growth. Choosing unpredictable paths in the face of commercial interests is counterintuitive. At critical historical moments, what standards and underlying logic guided BYD or Wang Chuanfu? The officially authorized book, “The Soul of the Engineer—BYD at 30, 1994-2024,” provides profound insights on this.

This book reveals why BYD stands out. Wang Chuanfu and his team of entrepreneurs embody a strong “engineer spirit.” BYD thrives on an “engineer culture.” A high number of engineers, a large proportion of frontline R&D staff, and significant investment in technology do not solely define “engineer culture.” These are merely reflections of it. In strategic challenges, when the company’s survival is uncertain, they still embrace technology and engineering to solve problems, just like in 1993 in Shenzhen. They show great passion for technology and enjoy the creation process. They place lower importance on commercial interests. This forms the foundation of engineer culture. We can use this standard to assess which companies share similar cultural traits. Like a person’s temperament, it can be polished or suppressed, but it won’t change. Once a company possesses this attribute, it centers on its engineers to create “future value.” Engineers receive fair treatment, respect, and status within the company. More importantly, the engineer team exhibits initiative and ambition, resulting in strong combat effectiveness. This cannot be explained by material incentives alone. Technology takes precedence, and investment is extremely high. From the start, Wang Chuanfu’s understanding of finance and market opportunities has been broad. In Shenzhen during that era, “act first, plan later” outweighed careful planning. A 90% certainty often meant lost opportunities and no battles to fight.

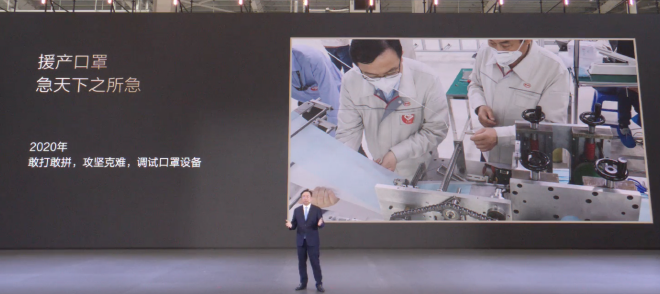

Everyone knows BYD started with batteries. They became the world’s top battery supplier through lower costs and higher quality. Their innovative management system played a key role. However, when they shifted from nickel-hydride to lithium batteries, they faced many problems. They solved these issues but Wang was determined to fully understand the electrochemical mechanisms of lithium batteries. BYD began quantitative research from the ground up. This was previously an academic endeavor due to its lack of profitability and high budget demands. BYD bought an X-ray spectrometer for 3.7 million yuan, more than their startup funds. They were the only private company to make such a purchase. BYD accumulated extensive research results and data on battery self-discharge, cycle life, and performance. At the time, this seemed like inefficient investment, but it laid the foundation for today’s leading global new energy vehicle company. By 2019, BYD still struggled to stand out. They sold 451,000 vehicles that year. In October of this year, their monthly sales exceeded 500,000. Their net profit, excluding non-recurring items, was just over 200 million yuan, while they invested over 8 billion in R&D. From a financial perspective, their R&D spending ratio was unsustainable. In 2008, BYD faced difficulties in their new energy transition. Sales dropped, profits fell, and dealers withdrew. Many partners left the company. Competitors set up recruitment booths outside BYD’s factory. In 2019, BYD remained stagnant. Over 11 years, their situation seemed unchanged. However, BYD made significant breakthroughs in technology and capabilities during this time. The public and market did not realize that BYD had developed substantial internal strength. The dazzling new technologies that emerged later were simply BYD’s prepared technological reserves responding to market demand. They took a path others had not. In early 2020, during the pandemic, BYD started producing masks. They needed masks, the country needed masks, and soon the world did too. Mask machines could not arrive quickly, and there was nowhere to buy enough. BYD chose to develop their own mask production line. They built a cleanroom of tens of thousands of square meters, with full-process manufacturing capabilities and a highly capable team. In just 24 days, BYD became the world’s largest mask manufacturer, producing 100 million masks daily. This was like re-enacting their rise to success.

In 2020, BYD promoted lithium iron phosphate batteries, blade batteries, and single-mode hybrids. At first, no one followed. Many mocked them. These technologies did not align with mainstream trends. Quickly, BYD made these technologies mainstream on its own. It did not need support; it became its own support. Today, battery manufacturers without lithium iron phosphate production lines have mostly fallen behind. Even the stubborn three major Korean companies have started small-scale production of lithium iron phosphate batteries. Three to four years have passed since BYD established its lithium iron phosphate route. In the rapidly evolving power battery industry, a three-month gap can be hard to bridge. BYD’s recent launches—Yisifang, Tianshen Zhi Yan, Yun Nian, Xuanji architecture, and the fifth-generation DN—are impressive. They showcase BYD’s long-term dominance in technology. Behind this success lies 14 years of commitment to new energy technology. Wang Chuanfu transitioned from a state-owned enterprise to entrepreneurship. He went from hand-making batteries to becoming the world’s top battery supplier. He entered the automotive industry against the odds. It seemed he made all the right moves. However, Wang did not pinpoint any clear business opportunity. He acknowledged a vague vision but dared to experiment. BYD’s approach ensures it remains unconventional. It does not follow established paths. Instead, it forges new ones. The electronics industry reflects this reality. Without mature suppliers for raw materials and equipment, companies must handle R&D, design, and production lines themselves. They provide their own components and start from scratch. BYD’s full industry chain layout stems from necessity. In the automotive sector, BYD owns most of its supporting suppliers, except for a few components like tires and glass. This practice continues today. BYD has taken extreme measures, such as owning a roll-on/roll-off shipping fleet. Waiting for shipments overseas is not an option, and current shipping capacity is inadequate. BYD even acquires metal mines and smelting production lines. This marks the imprint of an immature era in the new energy industry. Unexpectedly, vertical integration has become BYD’s methodology and success formula. This seems to confuse cause and effect. Innovation and boldness are two sides of the same coin. From a business perspective, innovation carries strong uncertainty. It offers high rewards but also significant risks. Wang Chuanfu claims he has “tasted the sweetness of technology” and now emphasizes technological innovation. His innovative capacity grows with his technology reserves. Initially, he had to push hard to gain momentum. However, after becoming a large enterprise, merely maintaining the status quo can lead to success. This weakens the drive for innovation and makes companies reluctant to invest in high-risk projects. This is the “big company disease.” Yet, BYD still exhibits the vigor of a startup. In contrast, some multinational competitors hesitate. They invest heavily in existing technology and new energy but remain cautious, showing little willingness to take risks. On the surface, it seems like an efficiency issue in research and development. In reality, it is a problem of guiding principles.

Wang Chuanfu said, “Engineers and talent are BYD’s most valuable assets. Reflecting on our journey, BYD’s R&D and development mirror the growth of Chinese brands.” BYD now has 11 major research institutes and 110,000 engineers. This year, nearly 80% of new hires are in R&D. “Without the wisdom of technical talent and an open, inclusive atmosphere, early innovation cannot happen.” Engineers focus on creating and providing solutions, not just on making money. Profit matters, but companies that ignore cash flow cannot survive long-term. Earning money is a byproduct of engineering thinking, not the main goal. Understanding this clarifies BYD’s approach.