On December 2, 2024, the 13th “National Traffic Safety Day” took place. Geely Galaxy partnered with the China Automotive Center, CCTV News, industry experts, and traffic police. They conducted a live broadcast of the first industry “whole vehicle safety devil series test” for the Geely Galaxy E5, exceeding national standards.

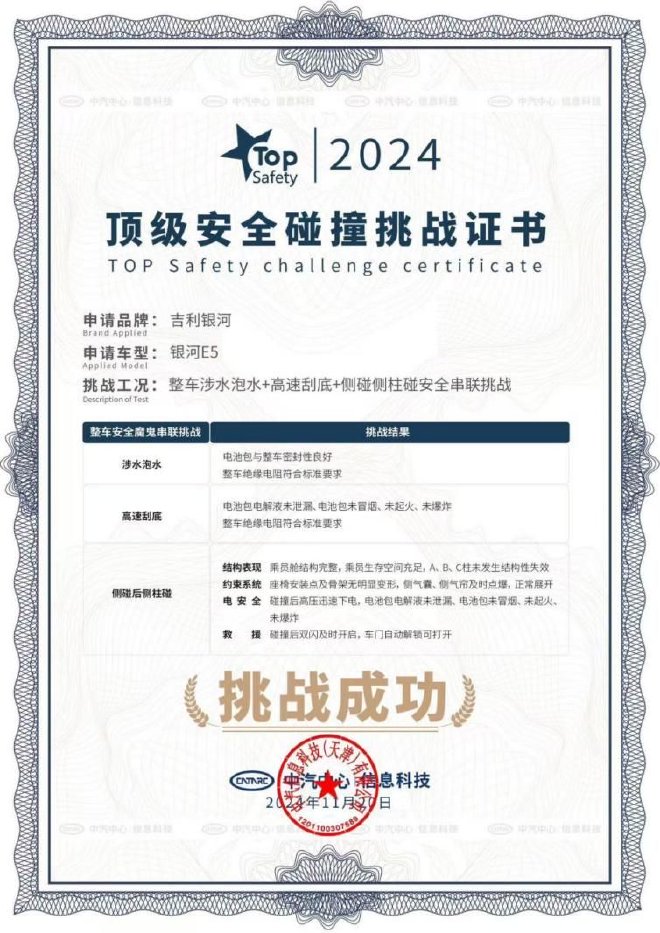

Under multiple witnesses, the Geely Galaxy E5 passed the rigorous tests. It exceeded national standards and simulated extreme real-world driving conditions. It received the TOP Safety certificate for top-level automotive crash safety in China. This sets the highest safety standard for electric vehicles in the 100,000 yuan (13770$) category.

The testing standards for this series of trials exceed national standards. The side impact and pole impact combination test is the only one of its kind. It is a pioneering high-difficulty test in the industry. The results show that the same Geely Galaxy E5 passed the extreme seawater surfing test, high-speed underbody scraping test, and the side impact and pole impact combination test. After a professional safety check, the core functionality remains normal. The vehicle can operate normally after being recharged in the lab. After testing the battery pack, we disassembled it. The structure remained intact. The cell arrangement was neat. There were no bulges or leaks. All wiring and functions showed no damage.

China’s new energy vehicle production has reached 10 million for the first time. More users face risks from water immersion, scraping, and side collisions. They now prioritize battery and vehicle safety. The Geely Galaxy E5 has passed rigorous tests. It shows that electric vehicles can ensure user safety with strong overall safety performance. This marks the beginning of an era focused on vehicle safety in new energy vehicles.

In the seawater extreme surfing test, the Geely Galaxy E5 achieved a wading depth of 400mm. This depth is four times the national standard’s requirement of 100mm. The immersion lasted 30 minutes, three times longer than the standard’s 10 minutes. The saltwater concentration of 3.5% is significantly stricter than the standard’s no requirement. In the high-speed underbody scraping test, the Geely Galaxy E5 tested at a speed of 35km/h. This speed exceeds the national standard of 30km/h. The collision energy increased by over 36%. In the unique side impact and side pole combination test, the 1400kg test vehicle far surpassed the national standard of 950kg. The sequential collisions from the side impact to the side pole significantly increased the impact on the test vehicle. This series of tests posed much greater challenges than typical user scenarios, providing redundant safety assurance for daily travel.

After the series of tests, the insulation resistance of the battery pack in the Geely Galaxy E5 test vehicle passed. The dry area showed no water intrusion. The passenger cabin structure remained mostly intact, providing ample space for occupants. The A, B, and C pillars did not experience structural instability. The seat mounting points and framework showed no significant deformation. The seat belts, side airbags, and curtain airbags deployed normally. The battery pack’s bottom guard showed no cracks, only slight deformation. The battery electrolyte showed no leaks. The cells experienced no compression. The battery pack did not exhibit thermal runaway, such as fire, smoke, or explosion. The hazard lights activated promptly. The vehicle unlocked automatically, and the door handles popped open.

The Geely Galaxy E5 proves its high safety and reliability. It offers ample escape space for users. Electric vehicle users face challenges like water hazards, flooding, and difficult road conditions. At risky intersections, the Geely Galaxy E5 ensures safety. The Geely Galaxy E5 reflects Geely’s global R&D capabilities. It meets global standards and uses advanced technology. This high-value smart vehicle inherits a global safety gene. It adheres to the four most authoritative safety standards. With the new generation Shield battery safety system and the first “military-grade” Shield knife battery, the Geely Galaxy E5 ranks first in safety standards.

The Geely Galaxy E5 features the Shield Short Knife battery pack. It meets the strictest IP68 and IPX9K waterproof standards. This design prevents dust, resists intense water spray, and withstands pressure. The CTB battery integration technology enhances vehicle consistency and airtightness. Geely employs advanced corrosion testing methods. They carefully select materials and design adhesive processes. They also implement stone impact protection, electrocoating, and adhesive waxing. These five steps ensure the vehicle’s waterproof and corrosion resistance. In September, the Geely Galaxy E5 traveled from Guiyang to Malaysia. It encountered severe flooding in Laos. Some roads had corrosive yellow mud over 30 cm deep. Despite this, all ten Geely Galaxy E5 vehicles safely passed through the flooded area. They continued for over 2000 km and reached Kuala Lumpur successfully.

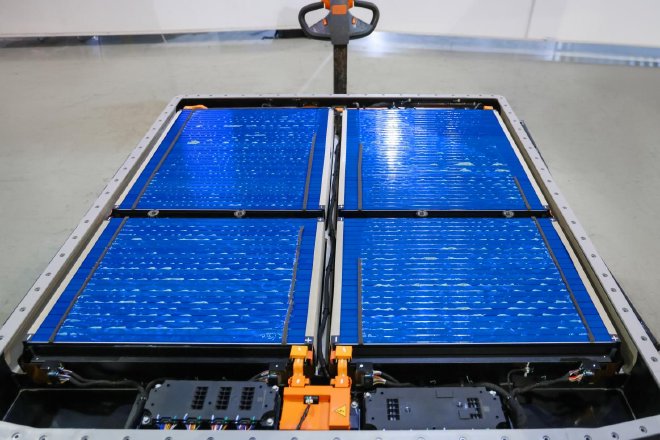

In a scraping scenario, the Geely Galaxy E5 uses a grid structure and four energy-absorbing cavity profiles. Its sandwich-like lower shell has a thickness of 2.6mm. The subframe crossbeam sits 10mm below the battery pack. This design provides multiple layers of protection for the battery pack. Tests showed that the battery pack’s bottom only sustained minor surface damage. There was no risk of thermal runaway. Notably, Geely was the first company in the industry to conduct scraping tests on new energy vehicles. It leads the establishment and promotion of industry standards with its own corporate standards.

At the intersection, the Geely Galaxy E5 features a high-strength cage body structure. It includes eight crossbeams and two threshold beams from the front battery pack to the rear. The design incorporates a “clover” energy absorption structure. This setup maximizes the dissipation of collision forces from all directions, protecting the battery and occupants. The battery pack connects to the “cross” battery compartment with 26 fixed points. This connection prevents instability in the seat crossbeam during side impacts, ensuring zero compression on the cells. The “grid” high-strength battery pack structure, along with advanced DP980 high-strength steel and aerospace-grade composite material PCM for the battery shell, enhances collision resistance and compressive strength.

The Geely Galaxy E5 test vehicle faced a side impact from two directions. Its hidden door handles popped out automatically, creating enough escape space for the user. On October 13, a Geely Galaxy E5 user in Wenzhou, Zhejiang, fell from a 10-meter-high slope while driving. The vehicle’s side airbags deployed in time, providing ample lateral protection during the roll. After the accident, the door handles fully extended, giving the user a chance to escape quickly. Geely Galaxy has fulfilled its promise by sharing this patent with the entire industry, aiming to build more trustworthy safety in new energy vehicles.

The testing event showcased extreme conditions. It confirmed that the Geely Galaxy E5 meets top safety standards. This reassures electric vehicle buyers about safety concerns. Since its launch on August 3, the Geely Galaxy E5 delivered over 60,000 units. It set new records for A-class electric SUVs. November sales reached 19,010 units. The Geely Star Wish, launched 49 days ago, also surpassed 30,000 deliveries. It achieved the fastest delivery rate for A0-class electric sedans. November sales hit 20,038 units, fueling the “Galaxy Speed.” On December 6, the Geely Galaxy Starship 7 EM-i, featuring the new generation Raytheon EM-i hybrid technology, will launch. The recent testing reinforces the safety of Geely Galaxy products. This could empower “Galaxy Speed” for even greater growth.